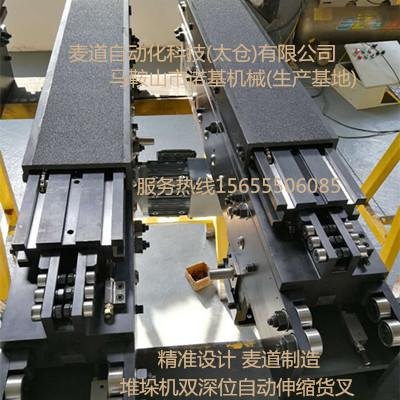

Telescopic fork of stacker

Model No.︰各种型号

Brand Name︰Mcdonnell Douglas

Country of Origin︰China

Unit Price︰CNY ¥ 55000 / pc

Minimum Order︰1 pc

Product Description

Automatic telescopic fork of stacker is widely used in three-dimensional storage, intelligent storage and logistics storage and transportation systems. it is often used in conjunction with automatic stacker. according to the instructions of control system, goods can be safely and quickly automatically stacked to a designated position, or the desired goods can be automatically removed from the shelves ( on the storage location )!

The automatic telescopic fork of the stacker can be divided into: ( 1 ) rack-and-pinion type telescopic fork: it adopts three or four sections ( or three or four sections, which can also be understood as single-depth and double-depth positions ). the single-depth fork is a complete fork telescopic mechanism ( double-depth fork is composed of front fork, upper middle fork, lower middle fork, fixed fork and guide roller ) composed of front fork, middle fork, and guide roller etc! The fixed fork is installed on the loading platform, the lower middle fork moves outward by about half of its own length under the drive of the gear and rack, the upper middle fork extends outward from the middle point of the lower middle fork plate, and the front fork extends outward from the middle point of the upper middle fork by a slightly shorter length than itself! ( 2 ) chain type telescopic fork: it consists of front fork, upper middle fork, lower middle fork, fixed fork and guide wheel, etc. the fixed fork is installed on the loading platform, and the fixed fork and upper and middle forks are all connected by chain wheels and chains!

Commonly used models are: md68 series / MDA 180 series / MDA 200 series / MDA 250 series / MDA 275 series, etc. different types of forks are configured according to different articles accessed and different load and load weights!

High - end configuration:

Fork material: using Nissan SCM 440 material;

Drive motor: sew motor, german brand;

Coder: using ProFi net ( bost ) brand coder, superior stability;

Limit switch: Omron, schneider brand switch, good quality assurance;

Rolling bearing: Nissan iko brand bearing with high load capacity, strong impact resistance, small friction resistance and high limit speed!

Special rack: high precision, up to national standard ( iso ) level 7, Japanese standard ( jis ) level 4, and American standard ( din ) level 7!

Transmission chain: Italian - made reggina brand chain, featuring abrasion resistance, high temperature resistance, low ductility, no elongation after stress, long service life, suitable for large-scale and long-term frequent use;

Payment Terms︰ Remittances

Product Image